Interview with ing. Franco Lambertini,

originally published in

Italian, in "Motociclismo d'Epoca)1",

issue August/September 2002

(best resolution: 1024 x 768)

Great Designers / Franco Lambertini, "MISTER V".

Face to face with the well known designer from Bologna, Italy, creator of the

V-twin engines, which were typical for Moto Morini for more than 20 years.

Freewheeling, he tells us about his long career, full of "juicy" background

stories and about a dream, which he would like to materialize.

ing. Franco Lambertini in his office with the original technical drawing of the

350cc V-twin.

At the moment, Mr. Lambertini is technical director at "Franco Morini Motori" (since 1999 the owners of

the brand-name "Moto Morini").

|

If today "the boss", Mr. Alfonso Morini, were still alive, he certainly would be

a happy person, firstly because (although for some years grass and weeds are growing at the center yard of his

company), his motorbikes have left a deep impression and secondly, because the name "Moto Morini" is

still able to create a lot of emotion amongst many. "The commendatore" (the boss) would have no regrets,

because, as long as he was active at the factory, the company always followed the route, which HE had choosen:

building motorbikes which were simple, reliable and user friendly.

The fact that the name Moto Morini reached such an important level in Italy, is in particular thanks to Franco Lambertini,

both a capable and competent technician, as well as a friendly and open person, who placed sincerity atop of his lifestyle.

It is a fact that Lambertini has interpreted - in a modern way - , the essence of the motorbikes built by Alfonso Morini.

He always stayed loyal to the philosophy of the "casa Bolognese ("house of Bologna"): simple, reliable and

fast. At Moto Morini he also was an innovator who used the lastest schedules and latest technical solutions, which were way

ahead of time, even ahead of products from Japan. |

By Alberto Pasi and Vittorio Crippa. "Motociclismo d'Epoca, September 2002".

Franco Lambertini was born in January 1944 in the area of Modena.

At an early age he inhaled "the air of engines" and chose to study precision- and fine technics. In 1961, after

a fierce apprenticeship as a mill operator and technical draftsman of gearwheels and presses and other mechanical tools,

he was hired by Ferrari, where he worked in all sorts of departments, like the departments of engines, gearboxes and even

car chassis. Here he perfected his education as a designer-technical draftsman. The experience at Ferrari was deteminative,

because he grew while co-operating with the best designers. So in 1967, and with the enthusiasm of his only 23 year old mind,

he left Ferrari for the small factory of sport- and racingcars "MWM" from Modena. Immediately, he became

"chief-designer". From his efforts, a Sport-Prototipo (prototype) 3.000cc was born with a V-8 engine and an angle

of 90o between the cylinders. For this car, he also made the design of the selfsupporting (monocoque) chassis. This

car was used - with good results - by the "Scuderia Serenissima" (from Venice), in various races. In 1970 Lambertini

joined Moto Morini. Although only 26 years of age, he was appointed to "principal of the design department". In 1972

he landed even a step higher on the ladder at Moto Morini and became "Technical Director".

After the cars, the motorbikes

The efforts of Lambertini at Moto Morini, rise above the heavy task of Chief-designer. The factory from Bologna found itself in a

crisis in the second half of the 1980s (Personal note: because the home market for motorbikes collapsed - CV) and this lead to the

takeover by "Cagiva". Lambertini tried to find financial support from the Italian government, (to save the company) and

designed a motorbike, powered by a V-twin engine, with both air- and watercooling and cylinderheads with four valves.

This new engine can be made in various versions between 350 and 750cc. Unfortunately, this engine was put aside aside by Cagiva.

By then, Cagiva had become the owner of the company from Bologna.

|

Some pictures of the "car past" of Franco Lambertini.

He started in 1961 at Ferrari and finished in 1969 at "Scuderia Serenissima". His "Sport Prototipo"

can be seen here at the start of the GP of Austria in 1969. |

|

|

|

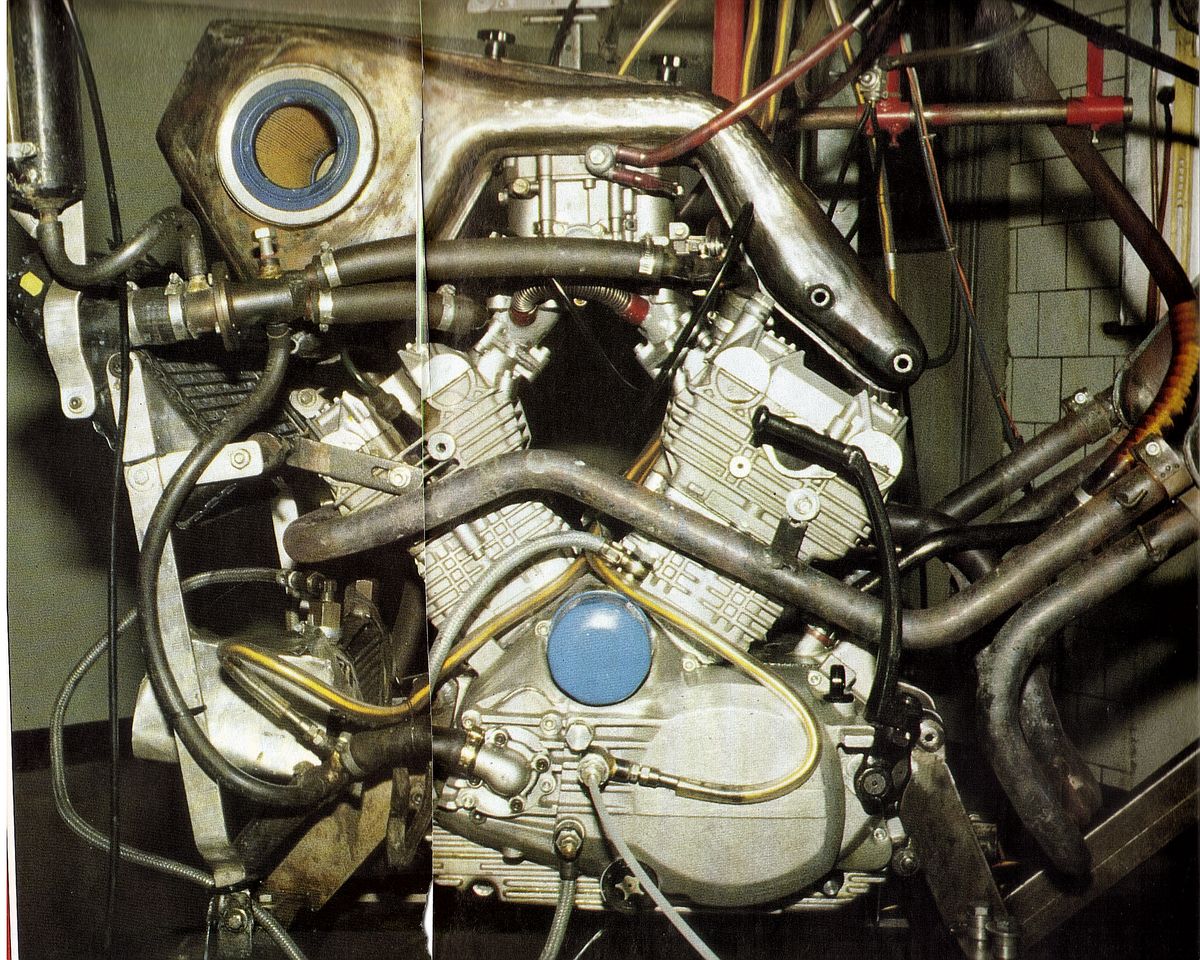

Test stand of the 720cc Morini v-twin... |

...and build into the frame of a prototype motorbike

|

The 3 litre V-8 engine (400hp). |

About Cagiva:

1) The name Ca-Gi-Va, stands for: Castiglioni-Giovanni-Varese, a relatively new company which had taken over the motorbike department from "Aermacchi H.-D." - CV).

2) Ca-Gi-Va first started producing suitcase locks and went into motorcycle business after Giovanni's sons Claudio and Gianfranco, themselves motorcycling enthousiasts,

entered the racing world by sponsoring young promising italian riders like V. Ferrari, etc. Years later they entered the motorcycle production market by buying the

Aermacchi H.-D. factory - AP).

|

ing. Lambertini is the third person from the right and

sits next to Mr. Alf Francis, who had been a mechanic

at "Stirling Moss". The "Serenissima" was founded by

the rich nobleman "Giovanni Volpi di Misurata" from

Venice. He also had Ferrari's and Maserati's. |

In the year 1989, Lambertini felt that the end of the glorious brandname Moto Morini was near. He took

the offer of Piaggio (Vespa) to become the director responsible for the department of "engine design", a separate company within the Piaggio conglomerate.

Under his management, various engines were introduced for all kinds of scooters, like a 50cc, 125cc, 150cc, both two stroke as well as four stroke engines, both air-

and watercooled. Also a 1,000cc twin-engine and many gearboxes for motorbikes which never made it into production, or was put aside by the marketing department of the

company.

Very important is his involvement with training and education of the staff of Piaggio. In the year 1995, he was appointed to "Responsible for the Motorbike-

Platform", a department with the aim to harmonise the design, development and production of engines, so production can be smoother (Piaggio is a very large

company).

|

Today Lambertini works for "Franco Morini Motori", again with the same tasks. At Franco Morini Motori we pay him a visit to spend a pleasant day with him.

In his office, which is plainly furnished, he is working on calculations to check the quality of the 900cc triple cylinder engine of the new Benelli motorbike. Benelli

has entrusted the essembly of all mass-production engines to Franco Morini Motori.

On the wall in his office we notice a large drawing of a V-twin engine. We will discuss the V-twin engine with Lambertini. Our interview starts with his car-history,

which educated Lambertini as a technician. As we have been friends with him for a long time, we take the liberty to speak to him in an informal manner and we will proceed

that way, during the rest of the interview.

The interview

Q: Often it is claimed, that car-technics and motorbike-technics are not compatible. What can you tell us about this, as you had your first experiences at Ferrari?

A: Yes, they are two completely different worlds, besides, Ferrari is unique in it's world. In Maranello I really learnt a lot, particular on the mentality. In

the car industry, especially in the field of racing, one aims for maximum technology and all the time experiments are made with new ideas. In car racing it seems like

there are unlimited funds, whereas, when developing a vehicle for the public, one has to carefully take the costs into consideration of the technical solutions, which

are choosen.

Q: How did you end up with Moto Morini?

A: When the Scuderia Serenissima was cancelled, I started looking for another

job. In the newspaper I saw an advertisement of Moto Morini, who were looking

for designers. So I applied. They had me do an assignment on the engine of the

Corsaro and so I was hired.

Q: What was the atmosphere like, when you started at Moto Morini?

A: It was an atmosphere soaked in an enormous passion. Mr. Marchesini was

working there, the Director of the Technical Department, which was very good.

Also Arnaldo Mastrangelo and especially Dante Lambertini, to whom I am not

related. Also many others, who were really living for Moto Morini. When I

applied to them, they had me do a technical exam, before I was hired. So I drew

the "flat head" for the Corsaro Regolarita. With this modification, the engine

produced 18 hp at the rear wheel. Now I can say that, although only 26 years of

age at the time and although I hardly had any experience regarding motorbikes,

my ideas were taken very seriously.

Q: Tell us about your "masterpiece", the 350cc V-twin.

A: It was born not so much later, than the time when I started working for Moto

Morini, so at the end of 1970 to be more precise. We were convinced that Morini

could not continue with the Corsaro as the only trump. Morini had to build a

motorbike, which was up to it's time, but it also had to fit in our tradition.

Moto Morini was a small firm and we had to attend the costs.

We then got the idea of a medium-class bike. Our thoughts went out to a bike,

which had to be light and compact, with good handling. It also had to have good

performance. I was convinced that the best structure of the engine (not only to

get optimum proportions between the frontal and lateral sizes), but also from an

aesthetical point of view, was the small V with an angle of 72o in linear

direction. Such an engine is only slightly wider than a single, because both

cylinders stay within the profile of the motorbike. It also offers the chance to

shape the header pipes properly.

In order to get proper cooling for the rear cylinder, I put both connecting rods

next to each other on the crankshaft and not like "twins",such as Harley-

Davidson. This way, the rear cylinder is not in line with the front cylinder,

but 5 cm (= 2 inches) out of line. The rear cylinder catches more air to cool.

Apart from that, the legs of the rider form a sort of deflector, which sends the

wind, when riding, to the rear cylinder.

Furthermore I shaped the header pipes (to the mufflers) in opposite directions

to prevent that the collector of the rear cylinder ending up in the hot air of

the front cylinder. This way, even under very heavy conditions, the temperature

difference between both cylinders is limited to a maximum of 15 o C, but in some

cases, it appears that the rear cylinder is even cooler than the front one.

I am still convinced that the "narrow V-twin" is the best possible engine for

motorbikes. Our work went so well at the time and without big problems, that we

were able to show a prototype at the Milan motorbike show of November 1971.

Little money, but a lot of dedication (love)

Q: In the beginning of the production of the 3½ there were many problems with

the connecting rods. How come?

A: The connection between the conrod and its head wasn't precise enough, there

was a small difference of 3-4 hundreds that escaped the checks. The tension

created for this reason on the connecting bolts first produced a bending stress

and finally broke them, with all the consequences. This problem appeared on the

first 200 to 250 engines, which all came back to us: damaged. For this reason,

it was nearly impossible to find the cause of the damage afterwards. After a

closer, more thorough investigation of all new parts the problem was finally

discovered. We changed to a different supplier and the problem was solved forever.

Q: One has always claimed that at Moto Morini there was very little money for

new investments. Did this influence your work a lot?

A: When I started work on the 350cc engine, I was told with emphasis to reduce

the cost to a maximum. That was the reason why I choose certain solutions, instead of

others. In 1972 the total cost of the complete production line of the 3½ was

reduced to about 600 million Italian Lira. (personal remark: at the time roughly

Euro 450.000 - CV). It does make sense: lower cost of production also mean a sharper

price for the buyer, even for spares. Lower cost of production also means a stronger

position on the motorcycle market in respect to competitors. Reduction of the production

costs should not influence the quality of the product and I am convinced that Moto Morini,

in this respect, never let it's customers down. |

After Moto Morini ing. Lambertini

worked for Piaggio. Here he worked on several projects, like the scooter "Sphera".

At Piaggio he also disigned a 1.000cc V-Twin for a heavy Gilera.

|

Q: But still, in the last years it was clear that at Moto Morini too much cost-

reduction was achieved.

His last year at Moto Morini was in 1989. During this last year he

worked on the development of a 125-150cc 4-stroke engine for a scooter on behalf of "SYM".

On the photo, Lambertini stands next to Mr. Fabio Taglioni of Ducati. Lambertini always

admired Mr. Taglioni in all working fields. Lambertini's greatest inspiration was Colin Chapman

of Lotus.

|

A: Yes, but this was typical for all small factories, who had to calculate

at night to see if the factory-doors could be opened again the next morning. This

was also the case at Morini. We had to count up to the last Lire but still,

everytime we were able to pay our suppliers in time, without ending up in red

figures.

Sometimes, the financial circumstances brought us into funny situations, which

can still make me smile, up to today. Like the time when we were busy developing

the 500cc engine. In the morning I came in to the workshop where I had put the

second prototype together (after lots of arguments) and I saw that a few men

were busy loading this engine into a van. So I asked what there was going on and

I got this answer: "But…did you not know about this? … We sold the engine to

the British importer ! …" Without getting angry I asked how they would supply

spares, as by then, nothing on the engine was registered in a technical drawing.

And so, we kept the prototype in the factory for a little while longer, for

further development.

Q: Despite everything, the 350cc engine still is a "concentrate" of

sophisticated technology...

A: Yes, I had choosen a few, for that time, very modern solutions. The

heads are flat, according to the "Heron" principal with the combustion chambers

in the pistons and parallel, straight(standing) valves to prevent problems when

valves and pistons would hit each other. Both intake and outlet ports were

developed very carefully to get a maximum turbulence in the heads. |

And, precisely, machining these channels caused us problems in the beginning, because

the apparatus, which had to machine the channels was not able to do so according to

the technical drawing. So we missed 2 or 3 hp. The funny part is that it took

quite some time to discover what caused the problem.

For the timing gear, I choose a rubber toothed belt. I was the first to use this

on a motorbike. In the beginning I even had to overcome the mis-trust of

Pirelli, because of their fear, due to the short length the belt would last only

shortly. But when we had an engine testrunning, it appeared that the rubber belt

lasted more than 200 hours. Later, when the kevlar belt was introduced, the

problems were solved for good.

|

|

|

An unknown prototype of 550cc with 60 hp.,

based on the 501 (507cc) engine. It was made at the end of the 80s. The project was

cancelled by the Board of Directors of Moto Morini. The engine was very modern with

hydraulic valve management and 4 valves per cylinder. It had liquid cooling, special

heads cylinder heads: the inlet valves were under an angle of 11o and the

outlet valves were under a 15o angle. When Cagiva took over Morini, the

engine was degraded to aircooling and also the bore x stoke dimensions were changed

from the original 78x57 mm to 73x65mm.

|

|

Mr. Gianni Marchetti, Moto Morini's Managing Director in the 70s and 80s.

|

The camshaft is located in the "V" between the cylinders, at the highest

possible place in order to keep the pushrods as short as possible. Further a

6-speed gearbox to get the maximum out of the engine, a solution only very few

streetbikes had at their disposal at the time. An electronic ignition, specially

developed for us by "Ducati Elettronica", to make the ignition free of

maintenance and to always have a strong spark under all circumstances.

Deliberately we choose a wide range of pre-ignition (from idle to maximum rpm)

to make starting of the engine easier.

Q: Why did you not supply the engine with a modern electric starter-engine

straightaway?

A: Originally I must say, the engine, was drawn with an electric starter, but

our administrator, Mr. Marchetti, who had to run the company in good and bad

times decided to cancel the e-starter to reduce the cost and also, because to

his opinion, a real motorbike rider, would not appreciate an electric starter.

On the other hand, like I said, the wide range of pre-ignition made that the

engine would always start easily, with one or two kicks only.

A study of the 1000cc V-twin from

the year 1987. Angle between the cylinders: 60o.

|

Q: What were the further developments of the 350cc?

A: Later, when e-starters were more common on motorbikes, we

also assembled them, but to be quite honest, that system only caused problems,

because it became a emergency solution. Also the choise to fix the gearlever

on the left was made later. From the beginning, I had drawn all parts of the

crankcases with the gearlever on the left, but then I had to re-make all

drawing mirrorwise. It cost me an extra week of work, but Mr. Marchetti decided

that "Morini-customers" were used to the gearlever on the right side, … and

there it had to stay !!!

A: In the first place the the 3½ Sport. In the beginning the engine of the Sport

was different to the standard engine on various points. The camshaft was

"hotter", the pistons were lighter and the compression was higher. But, because

of frequent errors and interchanged parts at the production department, we built

only one type of engine later. This meant that the difference in performance

between both models was owed to the better aerodynamic position of the rider on

the 350 Sport. The first Sport, the one with drumbrakes and spoked wheels, was

the best model with her performance versus weight. Later models with disc brakes

and light alloy rims were never able to match her performance. Another bike,

which I always thought was good, was the Kanguro 350, because it was a light and

very well handling machine; it went everywhere and aestetically it was a very

good model. Between all the engines, the 250cc was the best and most balanced

of the whole series.

We had to develop this model especially for the French market, as this engine

capacity was not penalised by taxes in this country. The most "juicy" engine was

the 501cc, which showed a fantastic torque. In these series of engines, modularity

was total: the casts of all parts of the crankcases was the same. It was easy to

switch from "mono" to "twin", simply by adding a special closing part in the cast,

so a hole appeared in the crankcase for the rear cylinder. Also the connecting rods

were the same. The ducts inside the head of the 125cc were the only difference

compared to the head of the 350cc. ; the oilpump only had a different neverending

screw and helical leading gear. There were more parts identical, like the same

gearbox for the 350, 250 and 125cc engines. |

From 350 to 500

Q: But some technical choices were at least strange. Why, to name one, was a dry

clutch used?

A: Yes, I know a dry clutch is harder in use and can be dosed less. Mr.

Marchetti decided on this, firstly, because it gave a sportive image to our

bikes and secondly, because the engine has not got an oilfilter that can be

changed, but only has a mesh- filter. Such a filter is not capable to stop all

pollution, coming from a wet clutch.

Prototype from 1986 with a 750cc V-twin engine (67o), 4-valve heads and

a single overhead camshaft. 85 hp, but there was a more sportive version planned.

The weight of the engine was only 50kg. The cranckcases could be cheaply casted

using all, still existing, moulds and machines from the 350-507 production line.

The investments were limited to 3.7 billion Italian Lira. The engine would cost

2 million Lira, against 3 million Lira of the Ducati 750cc engine....

|

Furthermore, a dry clutch has got smaller dimensions than a clutch in an

oilbath. Apart from this dry clutches are still used successfully in racing and

Moto Morini was always orientated in this direction.

Q: After the 350, the 500 came, but this motorbike was little disapointing for

some ....

A: One should consider well. The 500cc always was a splendid engine for me, but

one expected more difference in performance compared to the 350 engine. I should

say, it probably was possible to get some extra hp from the 500 engine, but at

Moto Morini we did not want to take any risks. More than the performance, we

wanted to emphasise the reliability of the engine and guarantee this to our

customers.

Finally, the extra VAT taxes of 38% (in Italy) reduced the numbers of sold

motorbikes a lot.

(Personal note: Motorbikes above 350cc in Italy had to pay the heavy 38% VAT

(tax rate). That is why you still find many bikes for sale in this class,

instead of the lighter types. You will find many Guzzi's V35 instead off V50,

many Ducati Pantah's 350 in stead off 500, more Morini's 350 than 500 and even

Laverda's 350 - CV).

Q: So far, we only spoke about technique, but Morinis were also appreciated

because of their plain, but well balanced appearance. Who drew the styling of

the various models?

A: We never had a design-department and, because of my origin from the car-

industry, I would have liked more straight lines for the 3½. But I was aware of

the fact that bikeriders would not have liked these straight lines. Mr.

Marchesini drew the K2 and I drew the 250 twin. We looked more at functionality

on the whole, as on aesthetics and that was decisive at the final shaping of the

bikes.

Q: Why did Moto Morini remain an Italian phenomenon and why did it not - in time

- expand on the international markets? |

A: We never had a design-department and, because of my origin from the car-

industry, I would have liked more straight lines for the 3½. But I was aware

of the fact that bikeriders would not have liked these straight lines. Mr. Marchesini

drew the K2 and I drew the 250 twin. We looked more at functionality on the whole,

as on aesthetics and that was decisive at the final shaping of the bikes.

Q: Why did Moto Morini remain an Italian phenomenon and why did it not - in time

- expand on the international markets?

A: Again, only a matter of money. To be able to sell in foreign countries one

should have created a decent network of dealers; one should have a branch office,

which can handle the market in question. But that costs a lot of money and we

did not dare to risk it. So our export was in the hands of only a few individual

dealers who - naturally - could not do more than they did on their own.

Every year, Franco Lambertini joins the meeting of Moto Morini Club Italy.

You can ask him (Moto Morini related) technical questions at www.motomorini.com

|

Q: To give our readers an idea: what was the production-record of Moto Morini in

one year?

A: In times of maximum success of the 3½, we did reach numbers of 5,000 up to

5,500 built and sold bikes per year.

Q: Now the chapter about the "500 Turbo".

Could it have become the key of succes for Moto Morini?

A: You are right, it was a challenge for us to be involved with such a complex

and difficult assignment. We started in 1976 with studying the "turbo". The turbo was

very much in fashion with the car-industry and would be used in due time by Renault

in the Formula 1. So we thought that this solution could provide Morini with a positive

image. We also started our search in this direction for another reason. Despite the

good sale results of the 350, Moto Morini still was a small company. To develop a heavy

engine from scratch was far too expensive for us, but we wanted to try to force our way

into the world of the "maxi's", with a unique |

and exclusive product. So we had little choice to really improve the performance. The

turbo was the simplest and most economical way to achieve this result. In other words:

from a 500cc turbo-engine is it possible to get equal or even better performance than

from a "normal" engine with nearly double the size. The advantage is the reduction of

weight. The problem were the dimensions, yes, because at the time, turbo's were used

for cars and in a car you don't have a problem with the required space. Due to the sizes

and the weight I put the solution of a "volume compressor" aside and I

started looking for a turbocompressor. In the begining we experimented with a

"KKK" turbine, but this unit was too big. But one day, a friend of mine told me

that he had discovered a very small turbine at the agricultural exhibition in

Verona. It was an

"IHI" turbine from Japan, imported by a firm in Caserta (near

Naples). I phoned them and they brought me into contact - very friendly - with

the Japanese.

Strange enough, the "IHI" told me that the

turbine

was still a prototype and they asked me why a motorbike factory would be interested

in such a turbine. They wanted to know from me where I would mount the turbo on the

motorbike, what compression from the turbine I was thinking off, what average

temperatures, what the right adjustment of the distribution phases would be and with

what compression ratio. |

|

the mass-produced IHI turbochargers for cars

|

Of course, I became suspicious and in my answers to the Japanese, I

deliberately sent some wrong parameters and information. Their answer was that they would

contact us at short notice. At the same time "Alfa Romeo Avio" offered us a turbo, which,

perhaps, would have been right as well. But the time passed and nobody turned up; not

from the Far East and not from Italy either. And so, from the beginning two years had

passed by and we had a few bookshelves full of papers and documents, but in concreto,

we had nothing ready. |

"By chance", two months after Honda introduced the CX 500 Turbo, the positive

answer came from Japan, that they were prepared to sell us the turbocompressor.

But in the mean time, we found out that the IHI Company also produced steel

forging- and cutting presses and that they had close commercial relations with

Honda. These are the final facts; I leave it to you to judge it. We presented

the 500 Turbo at the Milan exhibition in 1981 and also during the MotorShow of

Bologna. It was a fantastic bike with many progressive features, like the

muffler pipes underneath the buddyseat, a solution which is used a lot these

days, but we applied it first.

But the time, which had passed by from the beginning of the development, the

high cost and an excessive restraint at Moto Morini, finally led to the

canceling of the whole project. At those two shows, the people were lined up to

admire our 500cc Turbo. In any case, the publicity of this bike brought some

advantage for our make in a difficult period in relation to the numbers of sales.

The "turbo effect" caused our depots to empty of all the unsold stock of

production of a whole year. That was good, because production had gone down to

an absolute minimum, amongst other things, caused by various strikes at the

factory.

Apart from that Mrs. Gabriëlla Morini, the daughter of the "Commendatore", got

very tired of all the tension between the Unions and the Board of Management of

the company. Taking into considerartion that only few years before, working at

Morini was seen as a privilege in Bologna and surroundings and also that the

company was seen as one "Big Family". But unfortunately, the circumstances had

changed and it has - in my opinion - led to the sale of the company to the

Castglioni Brothers (Cagiva).

Q: You were talking about excessive restraint at Moto Morini, what do you mean

with that?

A: Very simple: the Board of Management mainly had people at age. These people

had seen the crisis of the 1960s and so, for every decision about a new

investment, they wavered at least ten times. Besides, the 125cc four stroke did

not sell as well as we wanted. We never dared to build a two stroke, which was

very much the fashion in the 1980s. This was a choice of conscience for us, but

we were not rewarded by the market.

But, although the technical discussions during meetings were really fierce, the

co-operation between us all, never ceased. That is why I was always very

associated with Moto Morini. They gave me, at all times, always complete trust,

by backing up my choises with a completely correct attitude towards my person,

under all circumstances. That is why I turned down all offers, made to me from

all sides. I only left Moto Morini - at the time already owned by Cagiva - when

it became clear that they wanted to close down Morini, because new, necessary

investments were lacking and because my new V-twin engine was cancelled from

their production plans.

I sincerely believed in the project, so much so, that I personally seeked for

government subsidies, based on Law nr. 46. The whole motorbike was very

progressive: the monocoque (self supporting frame) was made of pre-shaped

(pressed) steelplates with the rear-fork hinged in the engine. The engine itself

was working on the test-stand, with excellent results and also with excellent

prospects. But then Cagiva came with the story that there was no money for

further development and that they had plenty of engines already. So I took the

offer of Piaggio and left.

|

Q: Can we believe in a resurrection of Moto Morini?

A: At "Franco Morini" such an intention is present, but it is a very important step.

One should be prepared to make large investments and work for 2 to 3 years without a profit. That is

why they are presently looking for a suitable partner to realise these plans.

Q: How would you like to see Moto Morini in the future?

A: One should take "advantage" from the "emotional forces" which the name

Moto Morini, with her tradition, can still mobilize. Than a first-class product should be released.

A "naked bike", with a V-twin engine between 500 and 750cc. Natural, simple, compact,

economical to build, to sell, in use. A motorbike with a very defined "character". So, a bike

like my 3½ of 30 years ago.

Q: The drawing, which we saw hanging on the wall when we came in, should give you (the readers)

a hint in the right direction???!!!

The "happy ending" of this story was of course the official ressurection

of Moto Morini and the launch of the new models Corsaro 1200 in 2004 and 9½ a year later.

Remarkable fact: the V-1200cc engine of the new Corsaro (and 9½) was -- again -- designed by Franco Lambertini!!

This interview dates from September 2002. |

|

The closed factory of Moto Morini at the

Via Bergami in 1990.(Until 1992 production

took place in the Ducati factory - TK). |

|

|

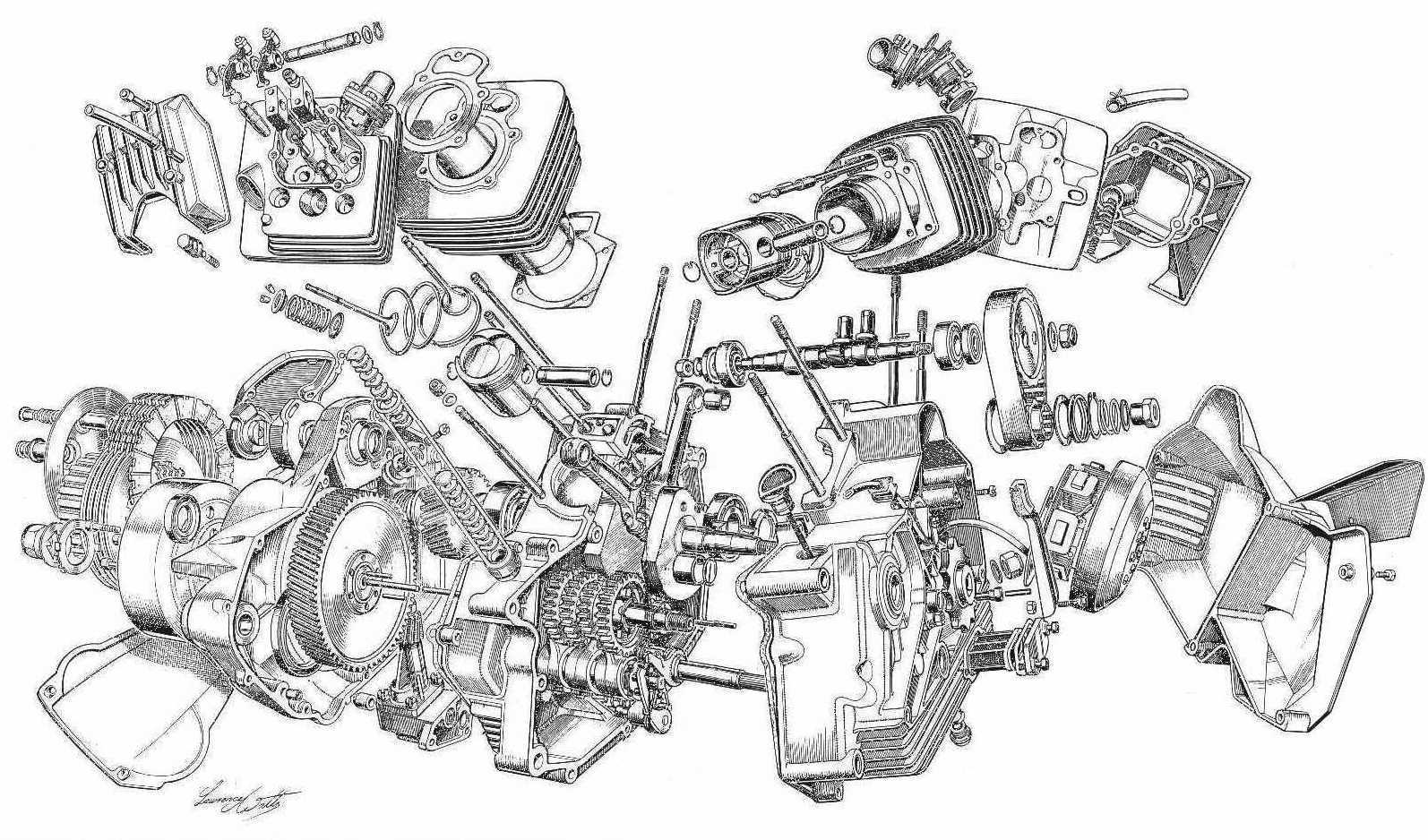

|

Lambertini's masterpiece: the V-twin engine |

The factory at Via Bergami 7 in better days. Most likely

first half of the 80s |

Now in use by a car dealer |

) 1 This English translation from the original Italian article in

MotoCiclismo d'Epoca of August/September 2002

is a co-production of the following Moto Morini fans:

- (Italian) Carlo Vergnano (CV), Italian to Dutch,

- (Swiss) Alberto Petraglio (AP), Italian to English,

- (English) John Stride, corrected our English

- (German) Achim Stollberg, scanned the pictures,

- (Dutch) Tony Kersbergen (TK), Dutch to English & co-ordination.

Please note:

- You can download the original interview - in Italian - from this site as a .pdf file (1.8 mB).

- On this website you can also read an older interview with ing. Franco Lambertini (1999).

- Special thanks to Mr. Carlo Perelli of MotoCiclismo d'Epoca, who granted permission for

publication of this internet version of the original article.

Back to index.

|